With 47 years of experience, SGP enables manufacturing and delivery of complete range of Propellers & Stern Gears in short span of time limits and with high quality & reliability. Our production facility built up on area of approximately 3000 sq meters. It includes our own Advance foundry Shop, Machining Department, Complete CNC Shop & Stock Keeping section which enables us to deliver bulk orders within committed span of time.

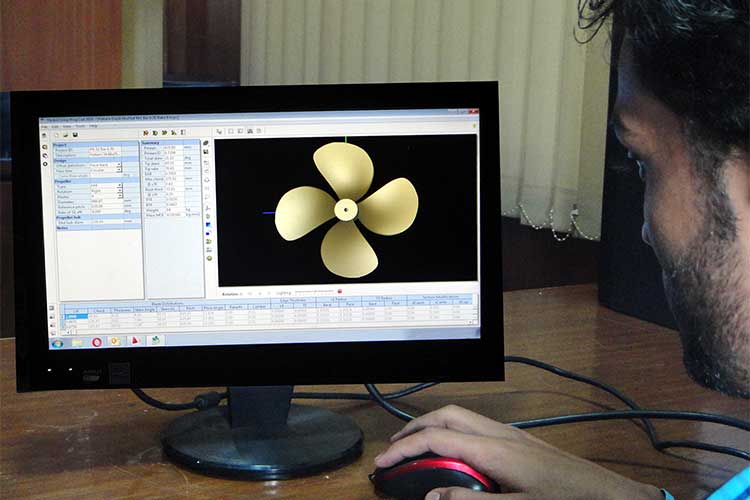

Our expertise & technical team always design the product with the view of meeting high performance requirements. Our own Pattern making shop enables us to review our design for the optimum performance. This has leaded us to achieve accuracy & have reduced production lead time.

We offer Propellers & other Propulsion components with mixture of alloys which includes Manganese bronze, Nickel Aluminum bronze, and Aluminum & Gun Metal. Our foundry is equipped with electrical furnaces with melting capacity of 5 tons for smoother & accurate castings. Utmost care is taken while molding so as to make sure that there is no porosity of inclusions in the propellers. Prior to pouring all liquid metal chemical analysis is carried out by Spectrometer to meet the desired specification of metal.

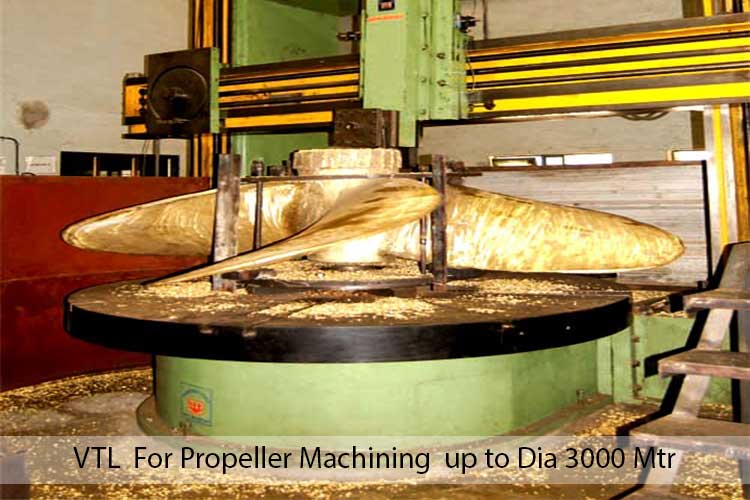

Our fully equipped machine shop carry out all operations activity for machining of products, with over 12 machines including CNC lathes, CNC VTL, Keys eater, Milling, CNC horizontal boring & auxiliary machines ensures the necessary capacity for machining of all our products.

A dedicated & skilled manpower with latest technology grinding facility to meet the tolerances of propellers as per ISO Class S, I & II as per the application. We have Vertical Machining center for our Specialize S Class Propellers grinding. Our Spectrometer, Balancing machines provide an added edge of advantage in terms of accuracy & quality.

We have In-house facility to carry out inspection of all our products which includes Spectrometer, Tensile testing M/C, Hardness Testing M/C, Impact Testing M/C, Pitchometer & SCHENK Dynamic Balancing M/C, and Static Balancing. Equipments are periodically calibrated as per ISO standard.

SGP is dedicated to maintain the quality of product even before manufacturing. From the Raw material Stage till conversation into finished product we have a team of Quality Assurance which continuously check & maintain the quality of product in every stage & process. Well maintain records & inspection analysis report provides confidence that quality will be fulfilled. We also provide our own Quality assurance certificate & Manufacturing Certificate for every single product we have manufactured.

SGP has obtained work approval certification from all major classification societies such as ABS, NKK, LR, DNV, and IRS. Also we provide technical advice on compliance with certification requirement.

© 2015 ShreeGajananPrasad. All rights reserved | Design by Phoenix360bs